Zulu Pods Inc. (ZPI) has been awarded a Phase 2 Small Business Innovation Research (SBIR) award by the Office of Naval Research (ONR), part of the Department of the Navy (DoN). The award will focus on continued efforts to develop novel, innovative fluid delivery systems for next generation jet engines used in Unmanned Aerial Vehicles (UAV). The technology will support broader Department of Defense initiatives aimed at rapidly developing and deploying thousands of affordable autonomous systems across various warfighting domains within 18 to 24 months.

The successful integration and application of a ZPod within relevant engine architecture marks a significant milestone for the company as focus begins to shift towards commercialization.

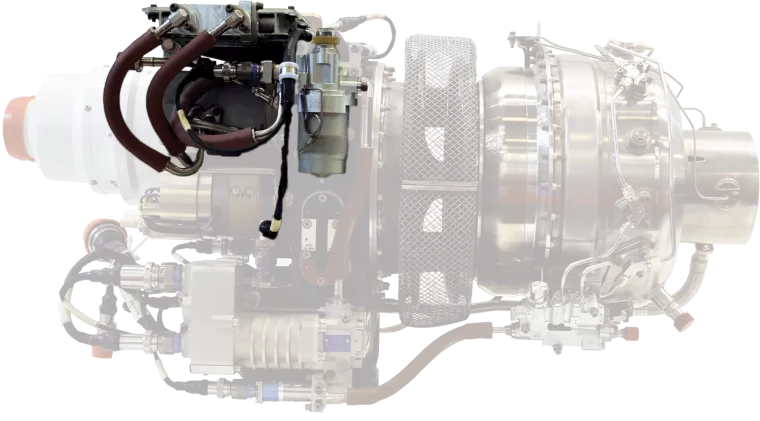

In Q2 2024, ZPI performed an engine test at the Amherst R&D facility utilizing its flagship product, the ZPod. The test compared a ZPod, which precisely delivers minimum lubrication to the engine bearing, against a combination of fuel and lubricant – an approach widely used throughout the industry today. The results demonstrated a significant reduction in lubricating fluid volume required, which enables more efficient use of fuel to extend range in mission critical applications.

The successful integration and application of a ZPod within relevant engine architecture marks a significant milestone for the company as focus begins to shift towards commercialization. In June 2024, ZPI leased a new production facility located in Northampton, Massachusetts with over 5,800 sq/ft of space for R&D, engineering, and manufacturing.

In addition to expanding their engineering and operations teams, procurement strategy will be a core focus as the U.S. Military emphasizes supply chain readiness, cost efficiency, and capacity as important qualifiers to adequately meet demand for rapid scale and deployment of munitions. "Supply chain risk mitigation is tantamount to technology capability in the eyes of our customers and end users," said Rob Sladen, CEO of ZPI. "Our priority is to begin investing in vertical integration early as we continue late stage TRL advancement to ensure we are adaptive to potentially high variability in production needs."

With a growing team, ZPI is naturally exploring new product and application segments with its fluid delivery technology in aerospace and defense. One area that shows promise is corrosion prevention on critical mechanical systems. The DoD reports spending approximately $20 billion annually on maintenance due to corrosion, almost 20% of every maintenance dollar. Corrosion also significantly affects the availability and safety of systems and equipment which can severely impact combat readiness.

The Anti-Corrosion Smart Pod (ACSP) builds off ZPI's patented oil pod technology with the introduction of health monitoring, data acquisition, and automated maintenance for long-term asset storage in maintenance bays, repair facilities, and overhaul depots. "Initial conversations with potential early adopters have been very positive," Sladen reported. "We see immense potential in reducing labor costs, performance degradation, and potential failures of critical mechanical systems that are stored for extended periods of time."